Reverse Circulation Hammer High Impact Frequency

High Impact Frequency Reverse Water Hammer / Water Well Drilling Hammer

Reverse Water Hammer Introduction

The RC hammer is used to remove rock samples which are pushed through the machine with compressed air. When air is blown down the annulus (ring-shaped structure) of the rod, the pressure shift creates a reverse circulation, bringing the cuttings up the inner tube. When the cuttings reach a deflector box at the top of the rig, the matter is moved through a hose attached to the top of the cyclone.

Reverse Circulation drilling, or RC drilling, is a method of drilling which uses dual wall drill rods that consist of an outer drill rod with an inner tube. These hollow inner tubes allow the drill cuttings to be transported back to the surface in a continuous, steady flow.

Unlike diamond drilling, it compiles sample rock cuttings instead of rock core. The drilling mechanism is most often a pneumatic reciprocating piston called a hammer, which in turn is driving a tungsten-steel drill bit, specifically made to be able to crush hard rock.

The drill cuttings will travel around the cyclone until they fall through the bottom opening into a sample bag. These bags are marked with the location and depth of the place where the samplewas collected and can be transported directly to the assay lab for analysis.

Reverse Water Hammer Parameters

Reverse circulation (RC) Hammer Quick Reference | ||

Size | RC Hammer Model | ROSCHEN RC Hammer Model |

3" | RC Hammer RE035 | ROS RC 35 |

4-4 1/2" | RC Hammer RE004 | ROS RC 40 |

RC Hammer RE540 | ROS RC 45 | |

5" | RC Hammer RE040 | ROS RC 50 |

RC Hammer RE542 | ROS RC 50 | |

RC Hammer RE543 | ROS RC 50 | |

RC Hammer RE545 | ROS RC 50 | |

5-5 1/2" | RC Hammer RE052 | ROS RC 55 |

RC Hammer RE547 | ROS RC 55 | |

5 1/2-5 3/4" | RC Hammer RE054 | ROS RC 55 |

RC Hammer RE140 | ROS RC 55 | |

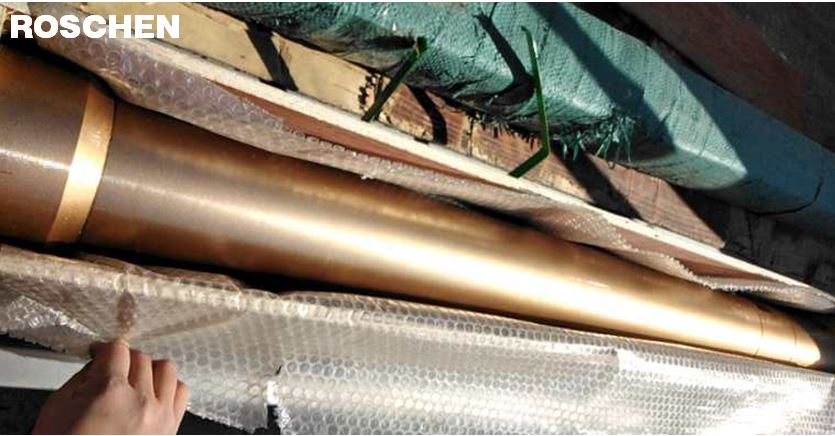

Reverse Water Hammer Details

The pride of workmanship and outstanding engineering make these hammers a superior value. Excellent depend ability, service, and suppo

Reverse Water Hammer Advantages:

1. Highly cost efficient

2. Outstanding engineering and manufacturing

3. Maximum material recovery, up to 98%

4. No cross contamination of samples

5. Locking key style shrouds

6. Handles injection of water, foam, oil, and polymers without performance loss

7. Delivers maximum drilling under water

8. Hammer can be fitted with back reaming subs

9. Additional air lift tubes

10. Manufactured using robust hardened metals for long life

11. Carburized pistons