Drill Pipe

Drill Pipe

Product Explanation:

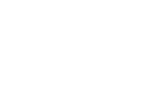

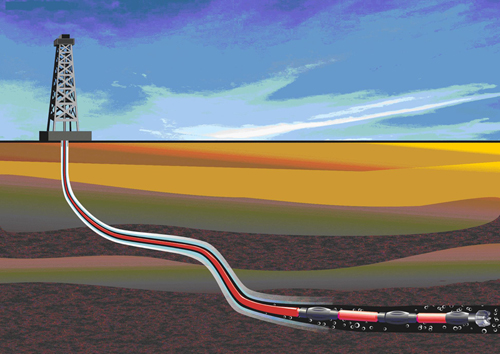

The drill pipe manufactured in accordance with API Spec 5D, API Spec 7, and API RP 7G. The steel grades include E75, X95, G105 and S135. The chemical composition of the steel is properly designed and strictly controlled. The special drill pipes such as anti-sulphur drill pipe, low-temperature drill pipe and high anti-torque drill pipe with double-shoulder tool joints (DSTJ).

Product Features:

. High precision in size and shape

. Good low-temperature toughness

. Excellent comprehensive mechanical properties

. High connection strength and seal ability

. Large inside diameter of tool joint

. High anti-torque property

. High fatigue strength and long fatigue life

Product types and specifications:

Specifications:

. API Spec 5D Specification for Drill Pipe

. API Spec 7 Specification for Rotary Drill Stem Elements

. API RP 7G Recommended Practice for Drill Stem Design and Operating Limits

Nominal Size | Weight Destination | Drill Pipe | Tool Joint | ||||||||

Pipe Body | Upset Type | Grade | Thread Type | OD of Pin & Box | I.D. of Pin | ||||||

Wall Thickness | |||||||||||

In (mm) | Kg/m | lb/ft | mm | in | mm | in | mm | in | |||

2 3/8 (60.3) | 9.90 | 6.65 | 7.11 | 0.280 | EU | E75 | NC26 | 85.7 | 3 3/8 | 44.45 | 1 3/4 |

X95 | NC26 | 85.7 | 3 3/8 | 44.45 | 1 3/4 | ||||||

G105 | NC26 | 85.7 | 3 3/8 | 44.45 | 1 3/4 | ||||||

2 7/8 (73.0) | 15.49 | 10.40 | 9.19 | 0.362 | EU | E75 | NC31 | 104.8 | 4 1/8 | 53.98 | 2 1/8 |

X95 | NC31 | 104.8 | 4 1/8 | 50.80 | 2 | ||||||

G105 | NC31 | 104.8 | 4 1/8 | 50.80 | 2 | ||||||

S135 | NC31 | 111.1 | 4 3/8 | 4l.28 | 1 5/8 | ||||||

3 1/2 (88.9) | 14.15 | 9.50 | 6.45 | 0.254 | EU | E75 | *NC38 31/2IF** | 120.7 | 4 3/4 | 68.26 | 2 11/16 |

19.81 | 13.30 | 9.35 | 0.368 | EU | E75 | NC38 | 1207.7 | 4 3/4 | 68.26 | 2 11/16 | |

X95 | NC38 | 127.0 | 5 | 65.09 | 2 9/16 | ||||||

G105 | NC38 | 127.0 | 5 | 61.91 | 2 7/16 | ||||||

S135 | NC38 | 127.0 | 5 | 53.98 | 2 1/8 | ||||||

23.09 | 15.50 | 11.40 | 0.449 | EU | E75 | NC38 | 127.0 | 5 | 68.26 | 2 9/16 | |

X95 | NC38 | 127.0 | 5 | 65.09 | 2 7/16 | ||||||

G105 | NC38 | 127.0 | 5 | 61.91 | 2 1/8 | ||||||

S135 | *NC40 4FH** | 139.7 | 5 1/2 | 57.15 | 2 1/4 | ||||||

4 (101.6) | 20.85 | 14.00 | 8.38 | 0.330 | IU | E75 | NC40 | 133.4 | 5 1/4 | 71.44 | 2 13/16 |

X95 | NC40 | 133.4 | 5 1/4 | 68.26 | 2 11/16 | ||||||

G105 | NC40 | 139.7 | 5 1/2 | 61.91 | 2 7/16 | ||||||

S135 | NC40 | 139.7 | 5 1/2 | 50.80 | 2 | ||||||

EU | E75 | NC46 | 152.4 | 6 | 82.55 | 3 1/4 | |||||

X95 | NC46 | 152.4 | 6 | 82.55 | 3 1/4 | ||||||

G105 | NC46 | 152.4 | 6 | 82.55 | 3 1/4 | ||||||

S135 | NC46 | 152.4 | 6 | 76.20 | 3 | ||||||

4 1/2 (114.3) | 20.48 | 13.75 | 6.88 | 0.271 | IU | E75 | NC46 4IF | 152.4 | 6 | 85.73 | 3 3/8 |

EU | E75 | *NC50 41/2FH | 168.28 | 6 5/8 | 95.25 | 3 3/4 | |||||

24.73 | 16.60 | 8.56 | 0.337 | IEU | E75 | *NC46 41/2XH | 158.8 | 6 1/4 | 82.55 | 3 1/4 | |

X95 | *NC46 41/2XH | 158.8 | 6 1/4 | 76.20 | 3 | ||||||

G105 | *NC46 41/2XH | 158.8 | 6 1/4 | 76.20 | 3 | ||||||

S135 | *NC46 41/2XH | 158.8 | 6 1/4 | 69.85 | 2 3/4 | ||||||

EU | E75 | NC50 | 168.28 | 6 5/8 | 95.25 | 3 3/4 | |||||

X95 | NC50 | 168.28 | 6 5/8 | 95.25 | 3 3/4 | ||||||

G105 | NC50 | 168.28 | 6 5/8 | 95.25 | 3 3/4 | ||||||

S135 | NC50 | 168.28 | 6 5/8 | 95.25 | 3 3/4 | ||||||

29.79 | 20.00 | 10.92 | 0.430 | IEU | E75 | *NC46 41/2XH | 158.8 | 6 1/4 | 79.20 | 3 | |

X95 | *NC46 41/2XH | 158.8 | 6 1/4 | 69.85 | 2 3/4 | ||||||

G105 | *NC46 41/2XH | 158.8 | 6 1/4 | 63.50 | 2 1/2 | ||||||

S135 | *NC46 41/2XH | 158.8 | 6 1/4 | 57.15 | 2 1/4 | ||||||

EU | E75 | NC50 | 168.28 | 6 5/8 | 92.08 | 3 5/8 | |||||

X95 | NC50 | 168.28 | 6 5/8 | 88.90 | 3 1/2 | ||||||

G105 | NC50 | 168.28 | 6 5/8 | 88.90 | 3 1/2 | ||||||

S135 | NC50 | 168.28 | 6 5/8 | 76.20 | 3 | ||||||

5 (127.0) | 29.05 | 19.50 | 9.19 | 0.362 | IEU | E75 | NC50 | 168.28 | 6 5/8 | 95.25 | 3 3/4 |

51/2FH | 177.8 | 7 | 88.90 | 3 1/2 | |||||||

X95 | NC50 | 168.28 | 6 5/8 | 88.90 | 3 1/2 | ||||||

51/2FH | 177.8 | 7 | 95.25 | 3 3/4 | |||||||

G105 | NC50 | 168.28 | 6 5/8 | 82.55 | 3 1/4 | ||||||

51/2FH | 177.8 | 7 | 95.25 | 3 3/4 | |||||||

S135 | NC50 | 168.28 | 6 5/8 | 69.85 | 2 3/4 | ||||||

51/2FH | 184.15 | 7 1/4 | 88.90 | 3 1/2 | |||||||

38.13 | 25.60 | 12.70 | 0.500 | IEU | E75 | NC50 | 168.28 | 6 5/8 | 88.90 | 3 1/2 | |

51/2FH | 177.8 | 7 | 88.90 | 3 1/2 | |||||||

X95 | NC50 | 168.28 | 6 5/8 | 76.20 | 3 | ||||||

51/2FH | 177.8 | 7 | 88.90 | 3 1/2 | |||||||

G105 | NC50 | 168.28 | 6 5/8 | 69.85 | 2 3/4 | ||||||

51/2FH | 184.15 | 7 1/4 | 88.90 | 3 1/2 | |||||||

S135 | 51/2FH | 184.15 | 7 1/4 | 82.55 | 3 1/4 | ||||||

5 1/2 (139.7) | 32.62 | 21.90 | 9.17 | 0.361 | IEU | E75 | 51/2FH | 177.8 | 7 | 101.60 | 4 |

X95 | 51/2FH | 177.8 | 7 | 95.25 | 3 3/4 | ||||||

G105 | 51/2FH | 184.15 | 7 1/4 | 88.90 | 3 1/2 | ||||||

S135 | 51/2FH | 184.15 | 7 1/2 | 76.20 | 3 | ||||||

36.79 | 24.70 | 10.54 | 0.415 | IEU | E75 | 51/2FH | 177.8 | 7 | 101.60 | 4 | |

X95 | 51/2FH | 184.15 | 7 1/4 | 88.90 | 3 1/2 | ||||||

G105 | 51/2FH | 184.15 | 7 1/4 | 88.90 | 3 1/2 | ||||||

S135 | 51/2FH | 190.50 | 7 1/2 | 76.20 | 3 | ||||||

6 5/8 (168.3) | 37.54 | 25.20 | 8.38 | 0.330 | IEU | E75 | 65/8FH | 203.20 | 8 | 127.00 | 5 |

X95 | 65/8FH | 203.20 | 8 | 127.00 | 5 | ||||||

G105 | 65/8FH | 209.55 | 8 1/4 | 120.65 | 4 3/4 | ||||||

S135 | 65/8FH | 215.90 | 8 1/2 | 107.95 | 4 1/4 | ||||||

41.29 | 27.70 | 9.19 | 0.362 | IEU | E75 | 65/8FH | 203.20 | 8 | 127.00 | 5 | |

X95 | 65/8FH | 209.55 | 8 1/4 | 120.65 | 4 3/4 | ||||||

G105 | 65/8FH | 209.55 | 8 1/4 | 120.65 | 4 3/4 | ||||||

S135 | 65/8FH | 215.90 | 8 1/2 | 107.95 | 4 1/4 | ||||||

*The former thread type is preferential.

**FH=full hole tool joint, IF=internal flush tool joint.

Notes:

① All of the sizes above as specified in API Spec 7.

② Any kind of combination of drill pipe and tool joint of other models and sizes is available.

③ Any kind of combination of drill pipe and left hand connection is available.

④ We can provide E75 and X95 products in large batches only.

⑤ We also can provide anti-sulphur drill pipe and low-temperature drill pipe.

⑥ We can provide high anti-torque drill pipe with double-shoulder tool joint (DSTJ) and other premium thread connections.