Secoroc Drill Pipe

Drill Pipe

Secoroc Drill Pipe catalog page

Secoroc Tubes -- Part of a Productive Package

Though their importance is often underestimated, tubes play an important role in DTH drilling -- regardless of application, rock type, hole depth, or drill rig. The key features of a high quality DTH tube are durability, accuracy, and manageability.

No Weak Links

Traditionally the threads and the joint between the tube and the end-pieces are vulnerable. To combat the problem we've friction-welded the joints for maximum strength and heat-treated the end-pieces for optimum durability.

Never Losing the Thread

Heat-treating the threads ensures not only a long service life, but also simplifies joining and breaking -- thereby cutting cycle time. To meet varying demands, we provide a selection of API threads. For applications where foam injection are used, we recommend the IF thread. Naturally, we also offer a wide range of subs and crossovers -- all made of high quality steel and heat-treated in the same way as tube end-pieces.

High Quality Tubing

Secoroc tubes are made from cold drawn tubing, providing a superior surface finish and tolerance compared to their hot-rolled counterparts. Our solution drastically reduces the risk of scaling -- the cause of so many premature hammer failures.

Pipes From 4-1/2" and Wall Thickness >0.346"

Hot Rolled Grade API J-55

Technical Spec:

| Tubing J-55 | Tool Joints, Adapters | ||

| Tensile Strength (RM) min. | 75,000 PSI | Surface Hardness | 58-62 HRC |

| Yield Strength (ReH) min. | 55,000 PSI | Depth | 0.080" |

| Elongation (A5) min. | 15% | Core Hardness | 32-36 HRC (approx. 300 HB) |

Hot rolled tubing fits inside the API N-80 standard, but it has the following shortcomings:

. The hot rolled surface is rough and can release scaling from the inside, which can enter into the hammer and cause severe damage to internal components.

. A rough surface gives higher friction losses, resulting in a higher pressure drop in the drill string.

. Wide tolerance of the wall thickness +/- 10-12%.

. Straightness tolerance not assigned. Must be straightened after welding.

. Production problems due to wide tolerances.

Pipes From 2-3/4" to 4-1/2" and Wall Thickness >0.346"

Hot Rolled Grade API J-55

Technical Spec:

| Tubing N-80 | Tool Joints, Adapters | ||

| Tensile Strength (RM) min. | 100,000 PSI | Surface Hardness | 58-62 HRC |

| Yield Strength (ReH) min. | 80,000 PSI | Depth | 0.080" |

| Elongation (A5) min. | 18% | Core Hardness | 32-36 HRC (approx. 300 HB) |

In order to improve the quality of DTH tubes we are now changing over to cold drawn tubing, and the features and benefits are as follows:

| Feature | Hot Rolled Tubing | Cold Drawn Tubing |

| Ovality | Included in the tolerance for the wall | Included in the tolerance for the wall |

| Wall Thickness | +/- 10-12% | +/- 3-4% |

| Straightness | N/A | 0.012"/ft |

Benefits in Short of Cold Drawn Tubing:

. Reliable wall thickness

. Less ovality, less risk of eccentric wear

. Better quality of the friction weld, less risk of concentricity of welding

. Better wear resistance due to increased hardness

. Reliable weights max 2-3% variance

. Less risk of damage to the tube from the straightening operation

. An overall weight reduction of our DTH tube assortment

. Still API N-80 standard for tubing

Friction Welding 2-3/4" to 5-1/2" ---- Over 5-1/2" Shrink Fit and Stick Welded

Friction Welding:

. Friction welding is a safe and efficient way to weld the end-pieces on to the tube material. The welding becomes stronger than the tube.

. Friction welding is a combination between friction and pressure.

. The end-pieces rotate with a speed of 480 RPM, and the pressure is between 1,015 PSI and 2,175 PSI depending on the tube diameter and wall thickness.

Friction Welded:

. Friction welding gives much stronger joints, compared with electrode welding, due to less risk of impure joints.

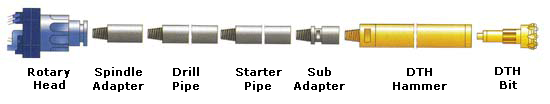

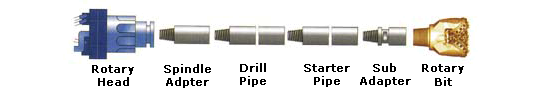

| Rotary Head | The power unit that rotates the drill string. |

| Spindle Adapter | Also called a "saver sub," threads into the rotary head and drill pipe, protects the threads of the rotary head, considered to be part of rotary head. |

| Drill Pipe | Available in a variety of lengths, diameters, wall thicknesses, and thread configurations. |

| Starter Pipe | Similar to the drill pipe, always the first pipe in the hole, usually shorter to compensate for the length of the DTH hammer, and with a greater wall thickness to withstand more abrasion as the hole is drilled. |

| Sub Adapter | Usually a short adapter, threaded on both ends in a male/female, female/female, male/male configuration. May be used to increase or decrease the thread diameter or change the thread style as needed for a particular application. |

| DHT Hammer/ DTH Bit | The percussive mechanism that drills the hole. Available in a wide range of diameters and styles depending on the application. |

| Rotary (Tricone) Bit | May take the place of the DTH Hammer and Bit in applications where percussive drilling is not required. |