Wireline Core barrel BQ, NQ, HQ, PQ

Wireline Core barrel AQ, BQ, NQ, HQ, PQ

Product description:

Wireline core barrel is a special type of core drilling, most commonly used for minerals exploration. Unlike some types of drilling, the aim of core drilling is not to dig a hole, but to retrieve a core sample-a long solid cylinder of rock that geologists can analyze to determine the composition of rock under the ground.

Size Available:

"Q" series AQ, BQ, NQ, HQ, PQ/AQTK, BQTK, BQ3, NQ2, NQ3, NQTT, HQ3, HQTT, PQ3, PQTT

T2 series T2 46, T2 56, T2 66, T2 76, T2 86, T2 101

T6 series T6 76, T6 86, T6 101, T6 116, T6 131, T6 146, T6S 101, T6S 116

T series T36, T46, T56, T66, T76, T86, T101, T116

TT series TT36, TT46, TT56, TTT66, TT76, TT86, TT101

Z series Z46, Z56, Z66, Z76, Z86, Z101, Z116, Z131, Z146

B series B36, B46, B56, B66, B76, B86, B101, B116, B131, B146

WF series NWF, HWF, PWF, SWF, UWF, ZWF

WT series RWT, EWT, AWT, BWT, NWT, HWT, PWT

WM series EWM, AWM, BWM, NWM, HWM

WG series EWG, AWG, BWG, NWG, HWG

Triple Tubes AMLC, NMLC, NMLC, HMLC, 4C, 6C, 8C, 10C

Minerals S75, S85, S95, S101, S116, S131, S146, S150, S168, S178, S194, S214

Others LTK48, LTK60, BGM, NGM, ADBG, TBW, TNW, ATW, BTW, NTW, NXD3, AX, NX, HX, NXC, AXT, T6H, 4 9/16, NWD4, 412F, SK6L146, TT46, TB56, TS116, CHD101.

Diamond bits Crown Shape and Applications:

Flat: Applicable to drilling different levels of hardness or abrasive formation, generally for single and dual tube drill bits

Semi-round: Good distribution of the diamond at bit face, adapt to a small broken or loose formation, applicable to drilling medium-hard and hard formation

Ladder: Applicable to drilling medium -hard, broken or interbedded formations, hole deviation can be prevented

Applicable to drilling medium -hard, have good stability during the drilling

Bottom jetting: Bottom jetting applicable to drilling sedimentary or metamorphic formations which containing more power, high coring recovery rate and avoid excessive washout of core. We supply A-Gauge impregnated core bit:AQ, AW, AGM;

B-Gauge impregnated diamond core bit: BQ, BQ3, BTW, BX, LTK60;

N-gauge impregnated core bit:NQ, NQ2, NQ3, NMLC, TNW;

H-gauge impregnated core bit:HQ, HQ3, HMLC, HTW, HWF;

P-gauge impregnated core drilling bit:PQ, PQ3;

Diamond bits Crown Shape and Applications

Flat : Applicable to drilling different levels of hardness or abrasive formation,generally for single and dual tube drill bits

Semi-round : Good distribution of the diamond ar bit face, adapt to a small broken or loose formation,applicable to drilling medium-hard and hard formation

Ladder : Applicable to drilling medium -hard, broken or interbedded formations,hole deviation can be prevented

Applicable to drilling medium -hard,have good stability during the drilling

Bottom jetting : Bottom jetting applicable to drilling sedimentary or metamorphic formations which containing more power,high coring recovery rate and avoid excessive washout of core.

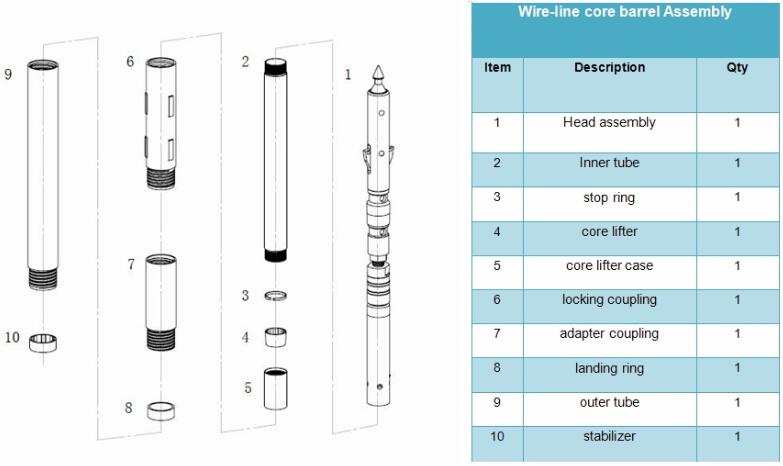

Structure:

The structure and work principle of wire line drilling tools , wire line drilling tools included core barrel assembly and overshot assembly: Outer tube assembly contains locking coupling, adapter coupling, landing ring, reaming shell, outer tube, outer tube and bit. inner tube assembly including spearhead point, detent mechanism, adjusting mechanism, Pensile institutions, tube assembly remove institutions, In position news agency and Core jams news agency etc.

Advantages of Wire-line core barrel

1. Save Time and manpower

No need to take every piece of the drill strings out to get the samples, saving a lot of time to hoist and disassemble the drill rods, by using wireline core barrel. And core barrel could be moved from the bottom of the hole without removing the drill rod string assembly.

In this process most of time is available for drilling and so speedier progress can be made with the same time spent when drilling.

2. Get larger core samples

For wireline drilling, the rods are made of fine high tensile steel. This makes them thin, so that the core can be as large as possible.

3. Making deep exploration

Wire line drilling is possible up to a depth of 1000m, or far more than that.

Double tube surface | ||||

Size( surface exploration drill | Matric system(mm) | Imperial system( in ) | ||

Hole diameter | Core diameter | Hole diameter | Core diameter | |

BQ | 60 | 36.4 | 2.36 | 1.43 |

NQ | 75.7 | 47.6 | 2.98 | 1.88 |

HQ | 96.1 | 63.5 | 3.78 | 2.5 |

PQ | 122.7 | 85 | 4.83 | 3.34 |

Triple tube surface | ||||

NQ3 | 75.7 | 45 | 2.98 | 1.78 |

HQ3 | 96.1 | 61.1 | 3.78 | 2.41 |

PQ3 | 122.7 | 83 | 4.83 | 3.27 |