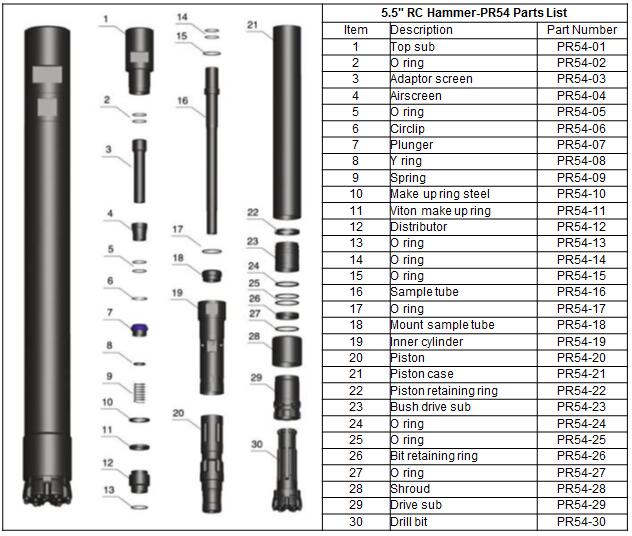

RC hammer PR54 5.5inch

RC hammer 5.5inch PR54

Product description:

Reverse circulation hammers are specifically designed for all kinds of exploration drilling, like deep hole and in-pit grade control applications. when you are exploring potential sites or working an existing mine, RC hammer will guarantee high performance, exceptional reliability and dependable support.

When breaking a Hammer down, avoid placing breakout tools in the mid-section of the cylinder (barrel). Recommended breakout points are 130mm from each end of the cylinder. Wrap around chain type breakouts are recommended (see diagram). When holding bits for breakout, use a secure plate or pot to grab the bit head, but never on the gauge row buttons.

RC hammers and bits are used in hole drilling in mines, hydrology and water well, geothermal well, geothermal air conditioning well, geologic exploration, gravel stratum, etc. Especial suitable for complicated formation (Formation loose, difficult to drilling and unstable of hole wall), exhausting for deep hole, environment protection.

Especial suitable for complicated formation (Formation loose, difficult to drilling and unstable of hole wall), exhausting for deep hole, environment protection.

We adjust button number, button configuration, button diameter to get ultra-performance and reduce the drilling cost for you according to your rock formation situation.

ROSCHEN RC bits sizes.

- RC bits 86mm -102mm for 3" RC hammer RE531

- RC bits 114mm -127mm for 4" RC hammer RE004

- RC bits 121mm -133mm for 4.5" RC hammer RE542/RE543

- RC bits 124mm - 138mm for 5" RC hammer RE545/PR40

- RC bits 133mm - 146mm para 5.5" RC hammer PR52/RE547/PR54/MX5456

Lenght(less bit) | Weight(Less bit) | External Dia. | Bit Shank | Hole Range | Connection Thread | |

1294 mm | 84.5 kgs | 130 mm | PR54 | 135-150 mm | 4.5" Remet 4.5" Metzke | |

Working Pressure | Impact Rate at 2.4MPa | Recommended Rotation Speed | Air Consumption | |||

1.7 MPa | 2.4 MPa | 3.0 MPa | ||||

1.5-3.5 MPa | 35 Hz | 25-40r/min. | 16m3/min | 22m3/min | 28m3/min | |

Product Features:

1. The reverse circulation DTH hammer provides large impact of torque and high efficiency of energy transfer while ensuring saving energy consumption.

2. It delivers high drilling efficiency due to strong capability of removing rock dust and flakes.

3. Air compression and reverse-flow fluid medium are all transported in the sealed double-wall drilling tool, thus avoiding direct contact with the borehole wall and maintaining stability of the wall. The reverse circulation hammer shows unique effect to complex and leakage formations.

4. Rock sample will be carried by the fluid medium and directly go back to the ground through the center hole of the drilling tool. It will not touch the wall of borehole, ensuring high quality of ore sample with no pollution.

5. Rock dust and flakes will be cleaned and discharged to a specific position through the center hole for central disposal, which ensured a prevention of dust and pollution, leads to improve working environment and enhance a longer service life of drilling equipment and attendance rate.

6. The reverse circulation DTH hammer comes with simple structure that accounts for its easy maintenance and handy worn parts replacement.

Reverse circulation hammer. In this method, compressed air or air foam fluid is used as the circulating medium. The annular medium between the inner and outer pipes of the double wall drill pipe is sent to the bottom of the hole, and then the inner tube is returned to the ground. The connection mode of the drilling tools used is: air gap double wall drill pipe special joint RC bit or DTH hammer. Among them, the air faucet has two channels, one is the intake channel, the other is the discharge channel. There are two kinds of special joints: guide joint and cross channel joint. The function of guide joint is to recycle the flushing medium in the annular gap between the inner and outer pipes, the annular gap between the guide bit and the hole wall, and return to the central channel along the central hole of the roller bit after passing through the hole bottom. The cross channel joint can make the circulating flushing medium wash the bottom of the hole with local positive circulation first, and then turn into reverse circulation to remove rock cuttings. Both the roller bit and the DTH hammer can be used. This method can realize "three sides integration" continuous drilling while drilling, flushing drilling and sampling, which changes the traditional production process of separating drilling and sampling. Drilling in medium and hard rock strata can greatly improve the drilling efficiency and significantly reduce the cost.