HDD Process: Heat Treatment

Roschen HDD Process: Heat Treatment

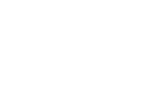

Roschen HDD provides only quench and tempered (Q&T) drill pipe. This process is entirely controlled through computerization to ensure every joint of pipe meets the mechanical properties planned. Batch furnaces are used, with multiple burners and circulation systems to provide an effectively controlled temperature throughout each furnace. The austenitize process heats every pipe tube for over an hour, in excess of 1600° F, to ensure a thorough heat soak.

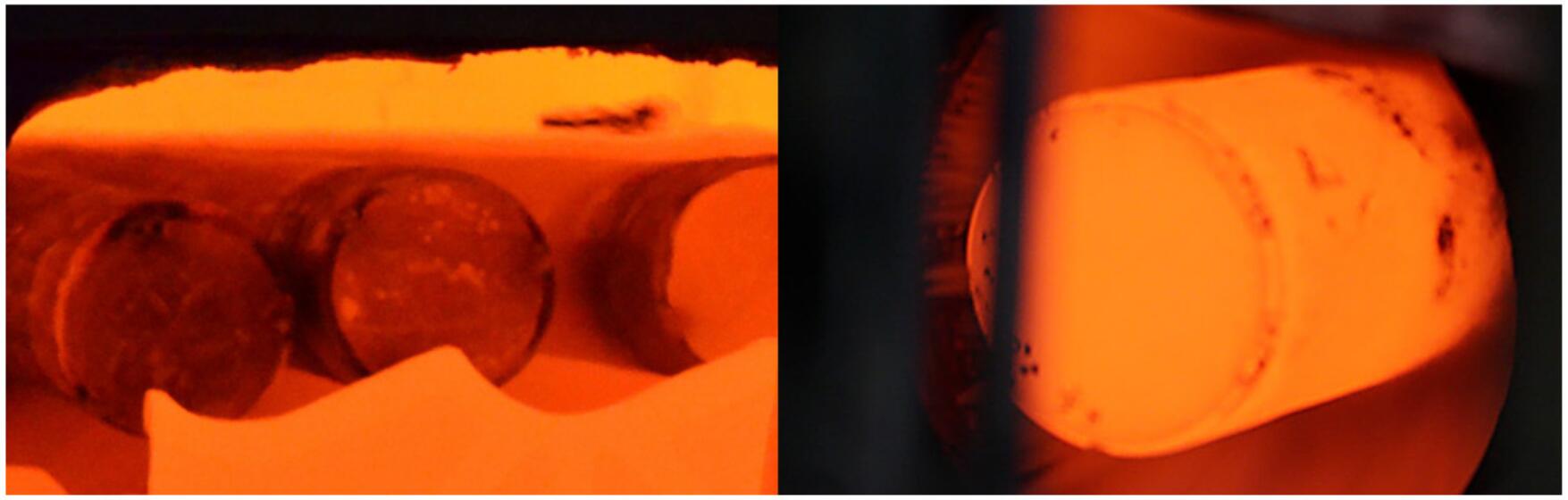

Then each individual joint enters the quench process, receiving in excess of 4,000 gallons water, per minute, through hundreds of controlled jets, to achieve a very rapid cooling, thereby, maximizing the formation of martensite. Each joint then goes into a secondary furnace for tempering at temperatures and time specifically designed to, make Roschen HDD's drill pipe exceed the toughness properties, while

meeting all the requirements of API and other specifications.