Drill Bits

Drill Bits

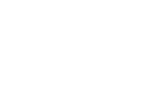

Varel High Energy Series Bit

Roschen provides only the best, newly manufactured rock bits designed for the unique rigorous conditions of HDD. No re-tips or re-circulated product, ever. Roschen uses the next generation in bit performance - the Varel High Energy (HE) Series Bit. The HE Series bits are able to withstand applications where the combination of bit weight and rotary speed is at the high end of the spectrum, and by so doing, deliver better performance and outcomes in critical application. HE Series bits are engineered as a solution to increasing demands on drill bits which require greater weight on bit (WOB) and higher rotations per minute (RPM) for faster drilling.

. HET Inserts - Improving the attributes of TCI overcomes the traditional trade-off between wear resistance and fracture toughness of TCI components and actually makes TCI components both harder and tougher.

. Mud Motor Hardfacing - For demanding motor applications, a generous application of tungsten carbide hardfacing is applied to the shirttail lower edge and leading edge of the bit leg to provide enchanced seal protection.

. Leading Edge Shirttail Inserts - Tungsten carbide inserts are placed along the leading edge of the shirttail providing additional wear resistance in motor applications commanding high RPM or where additional shirttail

protection is needed.

. Stabilization Inserts - Enchance standard shirttail patterns by providing bit stabilization and additional protection to the pressure compensator in high-angle applications or in deviation-prone formations.

. V-Jet™ Hydraulics Nozzles - Aimed flow stream produces better cone cleaning, which improves bit penetration

rates. V-Jets also maximize leg strength while minimizing overall bit length, helping deliver more hydraulic

horsepower to the hole bottom. The shorter overall bit length improves steerability on directional BHAs.

. Ball Retentation - Designed to retain the cone without carrying bit weight. This design technique prevents ball race spalling failures and extends bearing life.

. Thermally Stable Extreme Pressure (EP) Lubricant - Formaulated to work synergistics with the bearing materials. The lubricant maintains high relative viscosity even when the bearings are subject to extreme energy levels in demanding applications.

. Hardmetal Inlays - Critical bearing surfaces are presision-machined to provide superior bearing performance by reducing friction and wear.

. Precision, Silver-Plated Floating Elements - Reduce bearing heat generation and prolong bearing life at higher

rotary speeds.

. HSN High Aspect Ratio Seal - Provides positive sealing against contaminates with lower seal face contact stresses. This reduces the seal operating temperature and extends seal life.

. Shale Diverting Inserts / Shale Groove - More effective in diverting cutting away from seal, prolonging seal life.

. Stabilization Inserts - Enchance standard shirttail patterns by providing bit stabilization and additional protection to the pressure compensator in high-angle applications or in deviation-prone formations.

CROSS REFERENCE CHART

| IADC | Formation | Varel | Reed | Hughes | Smith | Security |

| Code | Christensen | |||||

| 437 | Soft | V437 | HP43A | ATJ11 | F1 | S82F |

| 447 | Soft | V447 | HP51 | AT11C | --- | S82DF |

| 517 | Soft to Medium | V517 | HP51X | ATJ11H | F15 | --- |

| 517 | Soft to Medium | V517C | HP51A | ATJ22 | F2 | S84F |

| 527 | Medium | V527 | HP52 | AT22C | F27 | S85CF |

| 537 | Medium | V537 | HP53A | AT33 | F3 | S86F |

| 547 | Medium | ETD38 | HP54 | ATJ33C | F37 | S88CF |

| 547 | Medium | ETD38G | --- | ATJ35C | --- | --- |

| 617 | Medium to Hard | ETD44 | HP61A | ATJ44 | F4/F45 | M84F |

| 617 | Medium to Hard | V617 | --- | ATJ44A | --- | --- |

| 627 | Medium to Hard | ETD45 | HP62 | ATJ44C | F47 | M88 |

| 627 | Medium to Hard | V627 | HP62A | ATJ55R | F5 | M89FT |

| 627 | Medium to Hard | --- | HP62-JA | ATJ44A | F47 | M88 |

| 637 | Hard | ETD55 | HP63 | ATJ55 | F57 | M89F |

| 737 | Hard | ETD85 | HP73 | ATJ77 | F7 | H87F |

| 837 | Extremely Hard | ETD95 | HP83 | ATJ99 | F9 | H100F |

HDD BIT SPECIFICATIONS

| Size Range | Milled Tooth | Tungsten Carbide | API Connection | Makeup Torque FT.-Lbs. | |||

| Inches | Millimeters | Lbs. | Kg. | Lbs. | Kb | ||

| 4 1/2 | 114 | 9 | 4.1 | 11 | 5 | 2 3/8 REG | 3,000-3,500 |

| 4 3/4 | 121 | 14 | 6.4 | 16 | 7.3 | 2 7/8 REG | 6,000-7,000 |

| 6 1/8-6 1/2 | 143/165 | 27 | 12.3 | 35 | 15.9 | 3 1/2 REG | 7,000-9,000 |

| 7 7/8 | 200 | 74 | 32.7 | 82 | 36.3 | 4 1/2 REG | 12,000-16,000 |

| 8 1/2-8 3/4 | 216-229 | 78 | 35.4 | 90 | 40.8 | 4 1/2 REG | 12,000-16,000 |

| 9 7/8 | 251 | 135 | 61.2 | 150 | 68 | 6 5/8 REG | 28,000-32,000 |

| 10 5/8 | 270 | 160 | 72.6 | 180 | 81.6 | 6 5/8 REG | 28,000-32,000 |

| 12 1/4 | 311 | 210 | 95.3 | 235 | 106.6 | 6 5/8 REG | 28,000-32,000 |

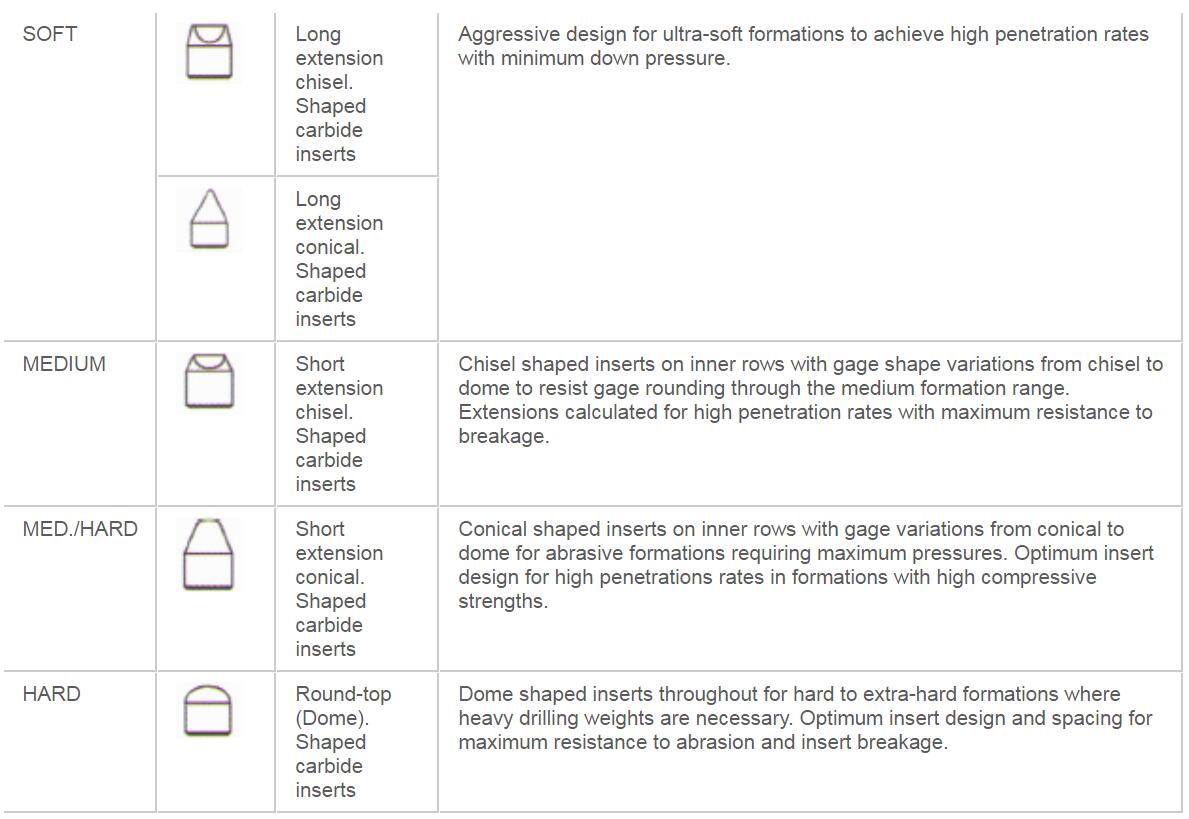

ABOUT CARBIDE INSERTS